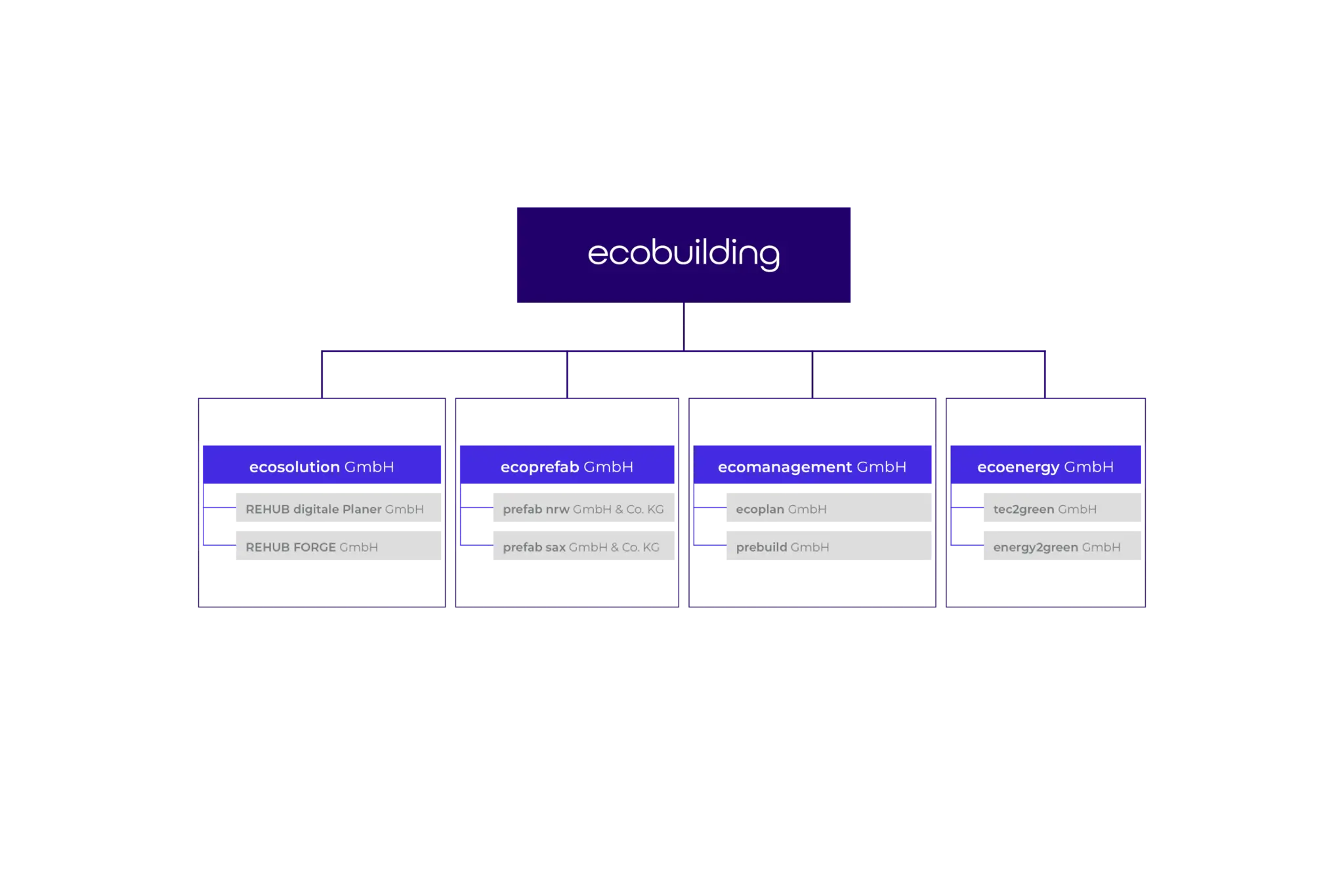

ecobuilding AG:

Sustainability through innovation

ecosolution

Architectural planning in new dimensions

Digital technologies form the necessary basis for a sustainable construction and real estate industry. This particularly applies to the circular construction industry that we are consistently striving for. The ecosolution GmbH consists of the REHUB digitale Planer GmbH and the REHUB FORGE GmbH. Through the process-optimized architectural planning based on digital twins, a circular and, therefore, sustainable project planning is intended to be enabled through the use of algorithms, data science, and artificial intelligence.

ecoprefab

More efficiency with serial prefabrication

The second pillar of ecobuilding AG is ecoprefab GmbH, under the umbrella of which prefab nrw GmbH & Co. KG and prefab sax GmbH & Co. KG are located as companies of our two new prefab plants which are still to be built in North Rhine-Westphalia and Saxony. The serial pre-production of construction components – also called prefabrication – combined with building information modelling is a vital building block to make construction more ecological, efficient, and cost-effective.

ecomanagement

For a smooth workflow in the development process

The ecomanagement GmbH acts as an interface between the other three corporate pillars of ecobuilding AG. As such, it organises, coordinates and monitors all processes within our construction projects to ensure smooth processes. It also provides consultancy and all related services. To this end, two new subsidiaries were founded: ecoplan GmbH is responsible for the digital planning that can steer the prefab plants. The prebuild GmbH is dedicated to assembling the prefabricated components previously manufactured in the factories on construction sites.

ecoenergy

Intelligent combination of innovative technologies

Our goal is to achieve a nearly carbon-neutral energy supply for our neighbourhoods by utilizing various innovative technologies for self-sufficient generation of renewable energy. An optimal combination and integration of these technologies make it possible to harness environmental energies on-site and store them for periods of low energy output. Our team of energy experts evaluates and develops customized solutions based on the specific conditions at each location.

Organization chart

Organization chart

Strategy

Climate-neutral and circular: The future of the construction industry

The real estate sector is under particular pressure to act. The building sector is responsible for approximately 30 percent of CO2 emissions in Germany. It is essential to develop smart and innovative solutions to ensure that residential and commercial spaces can be built and managed as climate-neutral as possible in the future. At the same time, it is crucial to maintain affordability.

Digital transformation

Digital technologies are the foundation for a sustainable, circular construction and real estate industry. For many years now, we have been heavily investing in the comprehensive digitization of planning and construction processes through BIM (Building Information Modeling).

By creating digital twins, we generate precise data models and databases of buildings during the planning phase. This allows us to apply internal algorithms, identify patterns, and derive automations for planning and control. Additionally, using AI, we create environmental assessments and life cost analyses. The data collected over the entire lifecycle of a building enables the retrieval of digital material passports, which are particularly useful for recycling. Our BIM experts also develop “BIM for Prefabrication” models as a link between planning and our future prefabrication plants, EMC 2.0, to ensure a highly efficient and smooth production process.

Prefabrication

To reduce CO2 emissions and conserve natural resources, an energy- and material-efficient construction of real estate is necessary. The escalating shortage of skilled workers is also forcing the industry to become more efficient. Simultaneously, the scarcity of housing requires shorter construction times and lower costs. We see a crucial solution to these challenges in linking digital planning with prefabrication, the serial prefabrication of components. Thanks to digital building plans, various components can be produced in high quality, preserving architectural uniqueness. Errors and waste are minimized. Prefabrication of walls and ceilings with reduced thickness, as well as the use of a higher proportion of recycled concrete, also saves building materials

In the future, in our new prefabrication plants EMC 2.0 in North Rhine-Westphalia and Saxony, we aim to manufacture not only ceilings and walls but also windows, insulation, conduits, balconies, stairs, supports, and pillars, achieving a prefabrication level of more than 60 percent.

Intelligent energy concepts

Currently, 65 percent of the emissions a building generates occur during its use, such as heating and cooling. The use of green environmental energies, both generally and in our industry, is therefore the key to combating climate change. Our goal is to supply buildings and entire neighbourhoods with renewable energy through the combination of various innovative technologies, making them climate-neutral in the future. With an intelligent mix of technology, we aim to utilize environmental energies on-site and store them for times of lower energy output. Our team of energy experts examines and develops individual solutions for each location. Technologies employed include photovoltaics, wind turbines, geothermal energy, groundwater heat pumps, wastewater heat exchangers, hydrogen-compatible peak-load systems, methane electrolysis, hydrogen block heating power plants, and more.

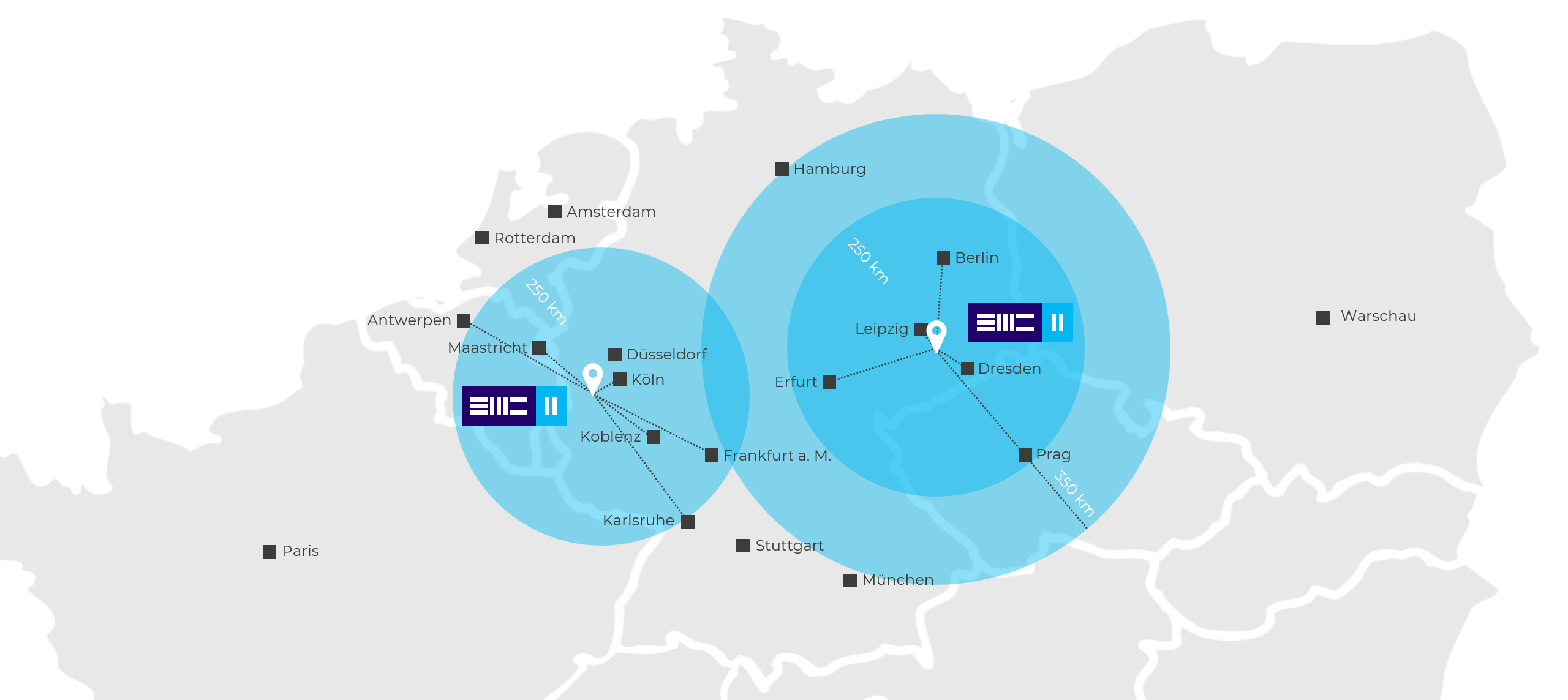

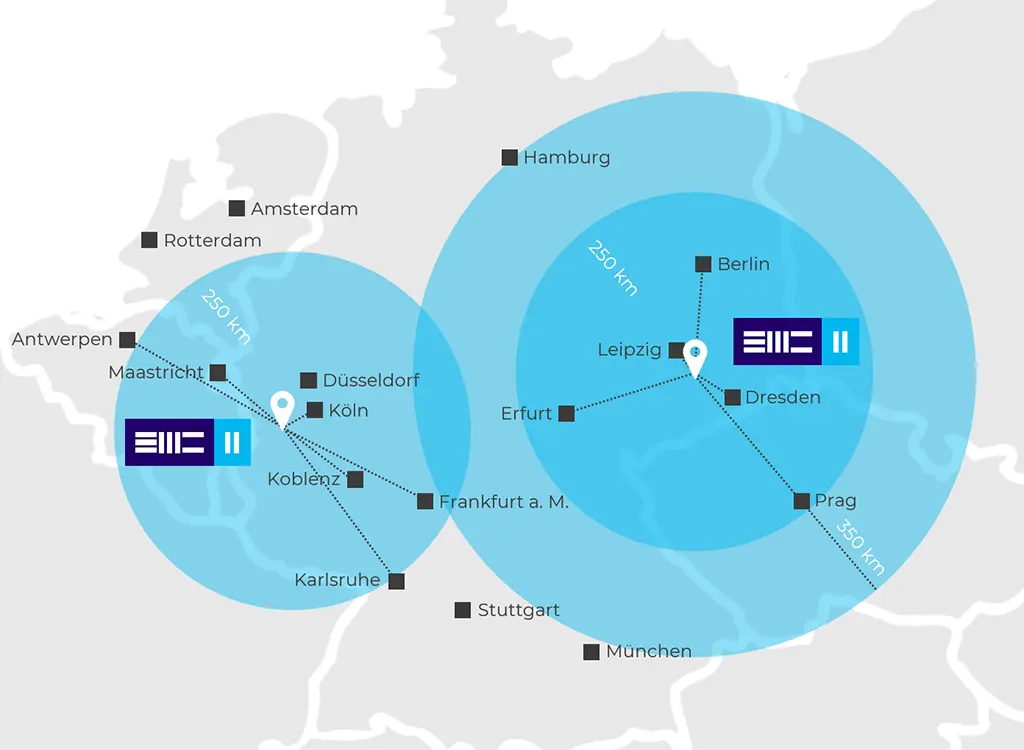

EMC 2.0

The first project under the umbrella of ecobuilding AG is the realization of two prefabrication plants, called EMC 2.0, scheduled to be built in 2024 and 2025 in North Rhine-Westphalia in Nörvenich and in Saxony in Thierbach, with an investment volume of more than 90 million euros each. The excellent infrastructure of the Thierbach site, including highway and rail connections, offers a logistical reach of up to 350 kilometres. The geographical location is crucial, ensuring that cost and environmental advantages are not negated by long-distance transportation of parts. At both locations, a wide range of components with significant manufacturing depth for residential and commercial construction will be produced. Through an efficient combination of BIM and prefabrication, construction is at least ten percent cheaper and requires only half the time compared to conventional methods. This generates a market demand that fully utilizes the capacity of the two modern plants beyond our own needs.

ecobuilding AG for reading

Find out more about ecobuilding AG in the new ecobuilding brochure

‘Sustainability through innovation’. Download now as PDF.